CRMa: Driving Innovation in Aircraft Maintenance

CRMa’s C.Lab leverages SOLIDWORKS to rapidly design, prototype, and deliver innovative aircraft maintenance solutions that enhance safety, efficiency, and precision.

Challenge

Establish the CRMa C.Lab as a “Center of Excellence” within Air France Industries KLM Engineering & Maintenance and invent, innovate, and develop safer, more efficient, and more cost-effective aircraft maintenance technologies and methodologies.

Solution

Implement SOLIDWORKS® Professional design software.

Results

- Delivered 25 major aircraft maintenance improvement technologies.

- Completed 250 prototyping research projects each year

- Saved 1,000 hours annually on aircraft brake piston cleaning

- Accelerated prototyping, testing, and machine design

In 2018 CRMa Aero Repair decided to launch the C.Lab, a dedicated space for converting innovative ideas into practical product solutions that help make airplane repairs safer, faster, and more efficient. As a Center of Excellence, CRMa specializes in maintenance, repair, and overhaul (MRO), serving a diverse roster of global customers, from airlines and original equipment manufacturers to part traders and independent MRO contractors. At the heart of Air France Industries KLM Engineering & Maintenance, CRMa is more than just an aviation service provider, it has become a hub of new product development.

C.Lab standardized its team on SOLIDWORKS Professional because of its intuitive user interface and robust product development capabilities. The C.Lab’s mission is simple: Take the best ideas for improving aircraft maintenance, whether from frontline technicians, employees, startups, universities, or manufacturers, and turn them into viable solutions. “Before we launched the C.Lab, it could take 8 to 10 months before an improvement idea was fully investigated,” Innovation Manager Erwan Guerin explains. “Now we design, prototype, and test emerging ideas immediately, which is why we needed a design system [like SOLIDWORKS CAD] that supports fast prototyping and testing, as well as machine design, tooling, and fixture development.”

Related Resources

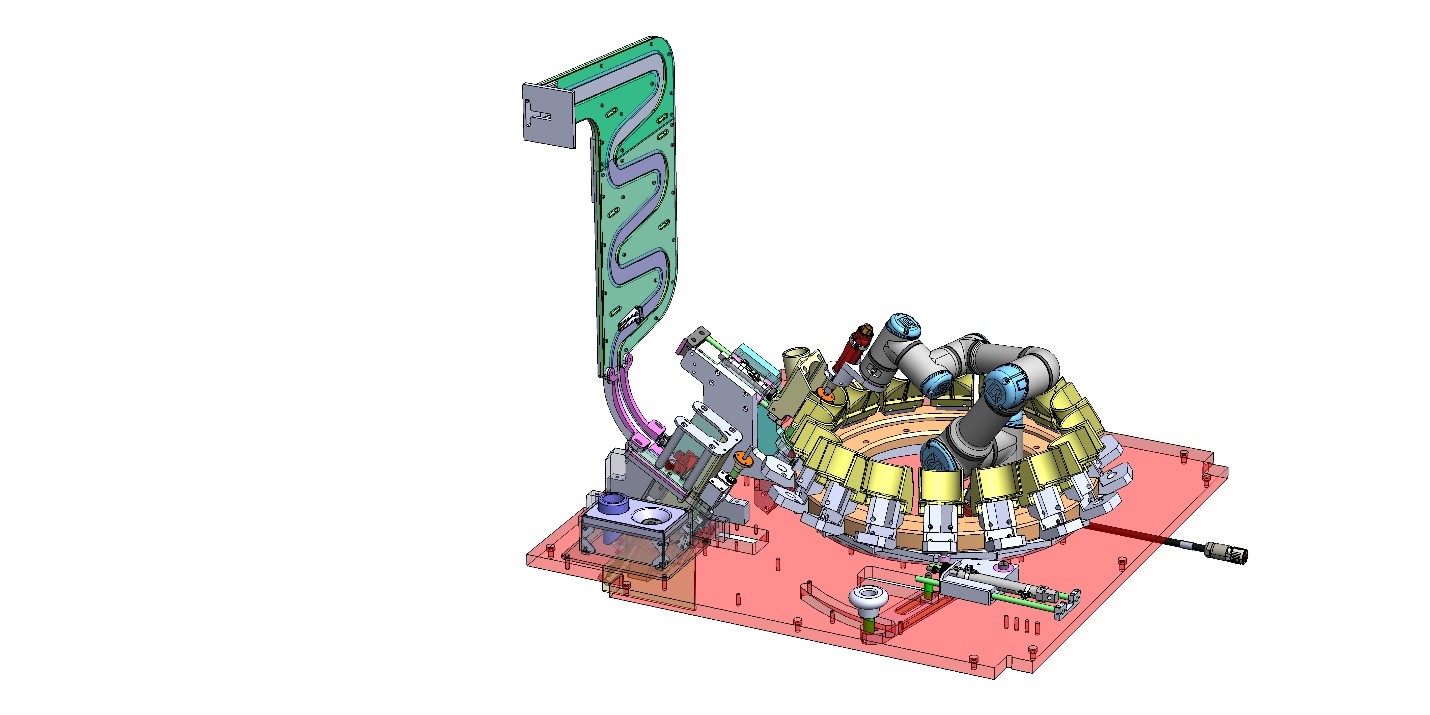

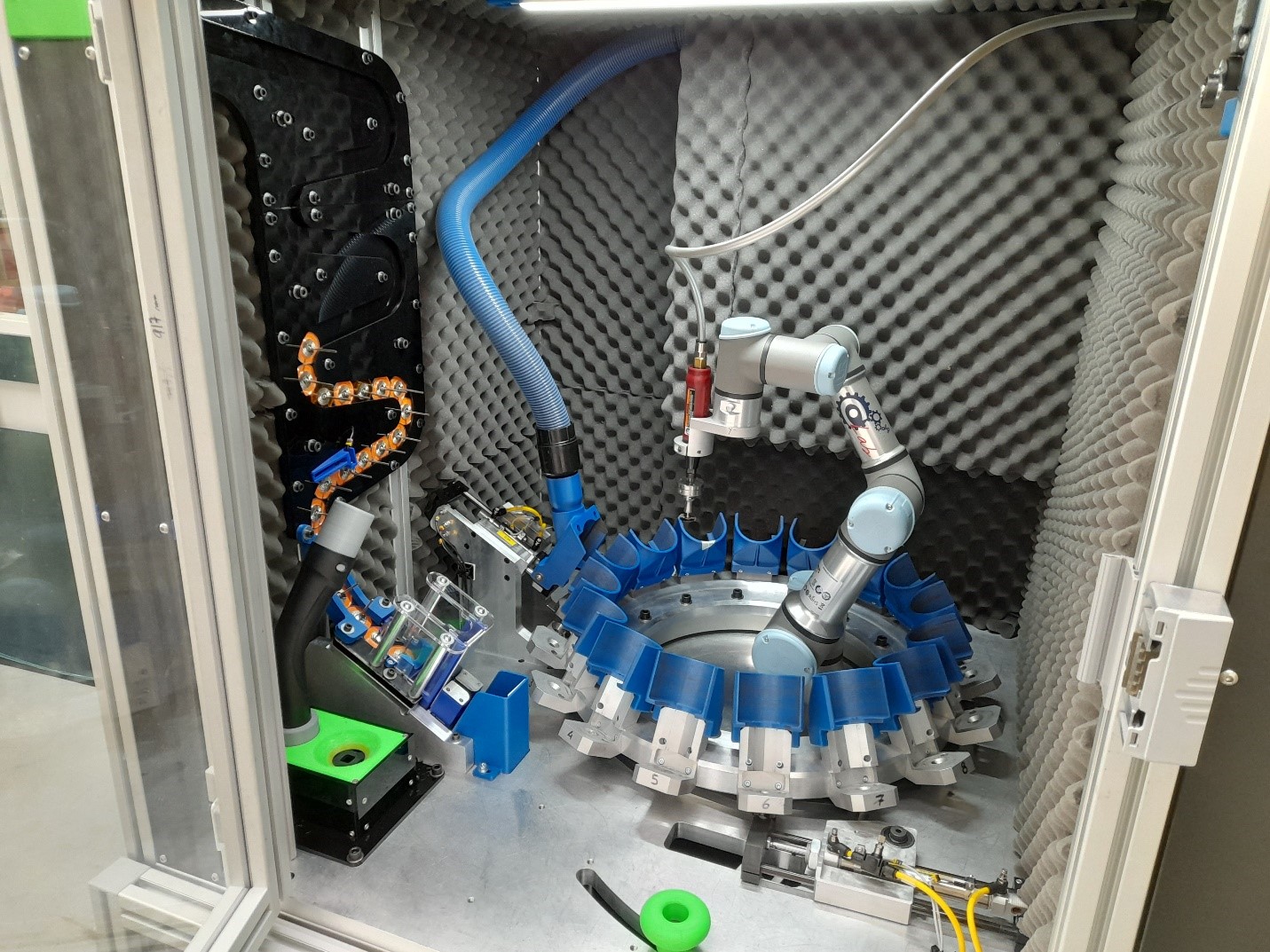

With SOLIDWORKS, we can design parts very fast, and it’s also quick and easy to make prototypes from SOLIDWORKS models. We also value the SOLIDWORKS large assembly design and dynamic motion capabilities because of our growing use of robotics. With these tools, we can make sure there are no interferences or collisions between parts, and simulate the movements of assemblies containing robotics to ensure that the robot moves and operates as designed.

Design, Develop, and Deliver FASTER

Since implementing SOLIDWORKS Professional software, the C.Lab has delivered 25 major aircraft maintenance improvement technologies and currently completes roughly 250 design, prototyping, and testing research projects each year. “We also value the SOLIDWORKS large assembly design and dynamic motion capabilities because of our growing use of robotics,” Guerin notes. “With these tools, we can make sure there are no interferences or collisions between parts and simulate the movements of assemblies containing robotics to ensure that the robot moves and operates as designed.”

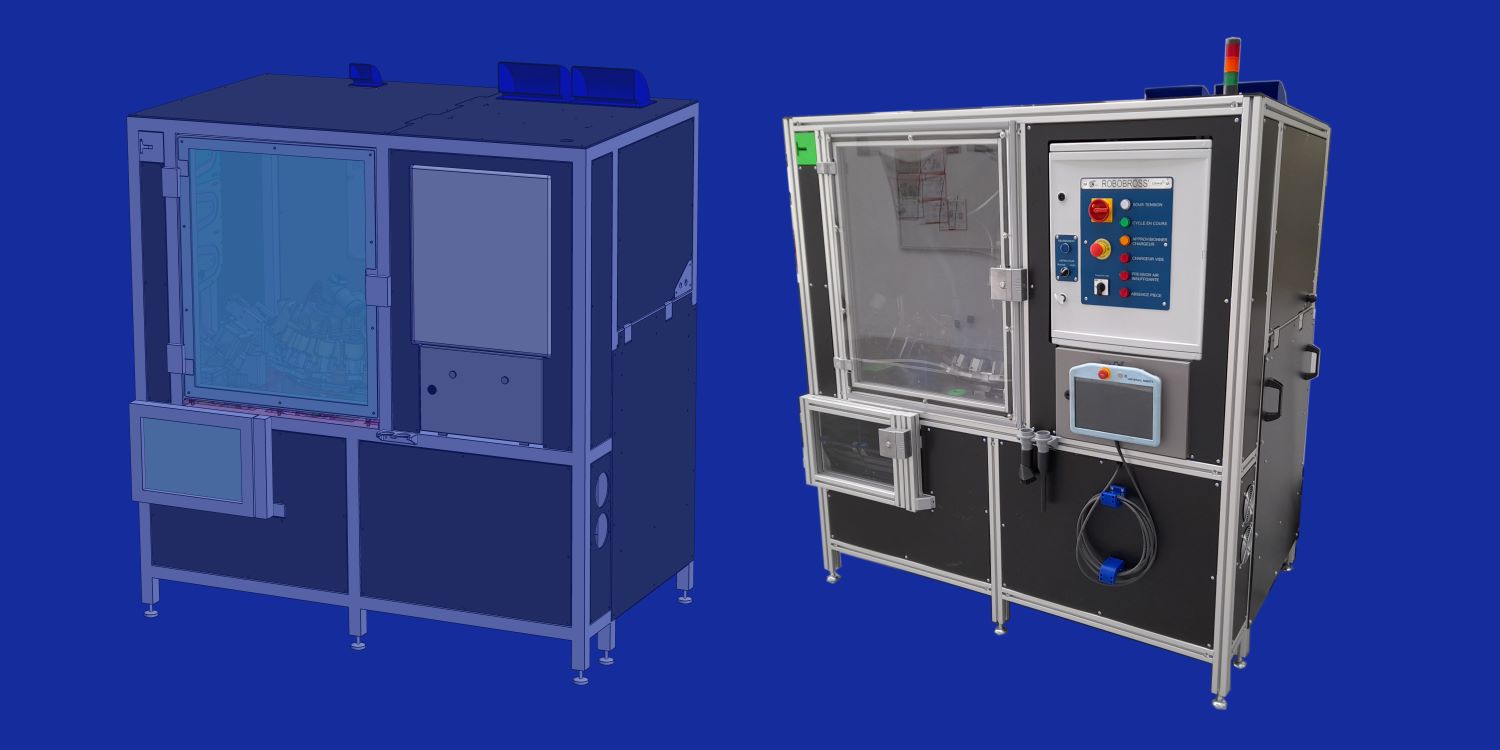

Although many of the aircraft maintenance innovations delivered by the C.Lab involve engine maintenance, the provider has also invented a robotics-based machine that cleans aircraft brake pistons that not only saves maintenance organizations roughly 1,000 maintenance hours each year but also removes a potential employee hazard.

“[One of] the biggest advantages of our aircraft-brake-piston-cleaning technology is the health and safety benefits,” Guerin says. Because aircraft brake pistons become clogged with carbon and oil deposits, they must be ground out with a grinding disk before being placed back into service. “Grinding out the pistons creates hazardous dust, which requires operators to wear some form of respiratory protection. Also, the vibration associated with the process can adversely affect maintenance employees who complete this repetitive task over many years.”

A Safer and More Efficient Work Environment

SOLIDWORKS has helped transform the C.Lab from a basic fabrication and prototyping unit to an innovation Center of Excellence by yearly delivery of three or four large pieces of equipment that improve aircraft maintenance. “When the C.Lab was established, it was expected to be just a fab lab running prototypes,” Guerin explains. “However, when we developed a highly impactful robotic-based machine during the first year, which was viewed as a [big] success, our focus shifted from just prototyping to making prototypes, machinery, and equipment.

“Today, we have mechanical, electrical, and robotics designers working in concert in SOLIDWORKS to make the best ideas for improving aircraft maintenance into concrete technologies that make maintenance safer, cleaner, more efficient, and less costly for our customers,” concludes Guerin.

Learn More About 3DEXPERIENCE Works and SOLIDWORKS

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.